We are Manufacturer, Supplier, Exporter (and also Servicing / Maintenance Services Provider) of Shell And Tube Heat Exchangers / Heat Condensers, Genuine Spares, Spare Parts from Pune, Maharashtra, India.

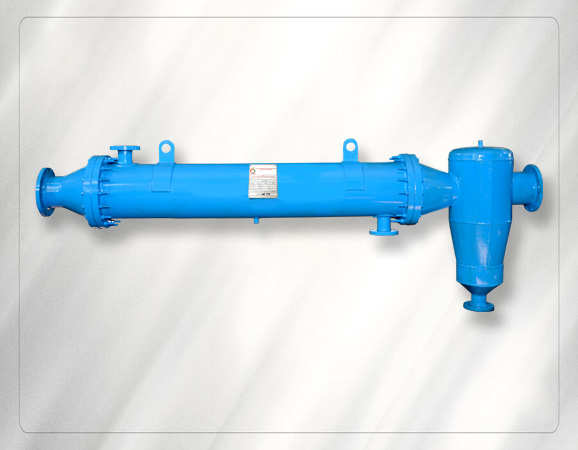

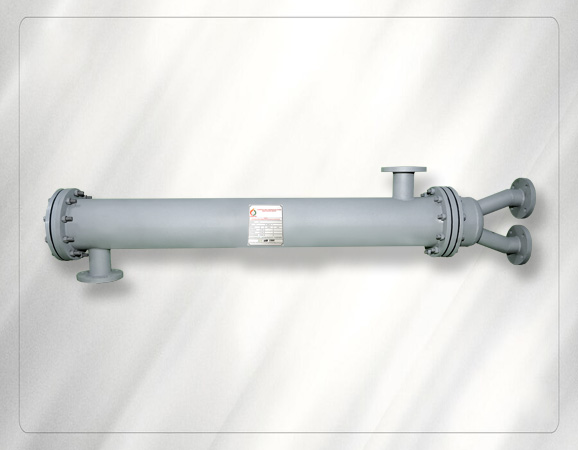

Shell And Tube Heat Exchangers are a versatile and durable choice for a wide range of industrial applications. At Eternitive Heat Transfer Solutions India Private Limited (EHTS), we specialize in manufacturing Shell And Tube Heat Exchangers tailored for various processes like heating, cooling, condensing, reboiling, and many others. Each exchanger is customized to meet specific requirements, especially for critical fluids and gases, ensuring reliable and efficient performance.

The technical expertise at EHTS allows us to construct Shell And Tube Heat Exchangers using a wide range of materials, suitable for the most demanding processes. We adhere to global standards, offering high-quality engineering and manufacturing as per ASME, PED, and other international codes.

EHTS employs advanced technology in the design and fabrication of Shell And Tube Heat Exchangers. Following TEMA guidelines, our exchangers are engineered for optimal thermal performance. We use software like HTRI and ChemCAD for precise thermal design, ensuring that each unit is well-suited to its specific application.

Our Shell And Tube Heat Exchangers are designed to meet rigorous mechanical standards, including ASME Sec. VIII Div. I, BS5500, and PED. We utilize SolidWorks for accurate mechanical design, allowing us to deliver custom solutions for a variety of industrial processes. EHTS has the capability to produce exchangers that can operate under high temperatures and pressures, catering to client-specific requirements.

EHTS specializes in fabricating Shell And Tube Heat Exchangers with a diverse range of materials, including stainless steel, titanium, copper alloys, Inconel, and more. This ensures compatibility with various fluids and gases, offering corrosion resistance and durability for the most challenging environments.

Our Shell And Tube Heat Exchangers offer the following features:

- Customizable to meet precise thermal and mechanical specifications.

- Suitable for high temperature and pressure applications.

- Wide selection of materials for construction, including corrosion-resistant alloys.

- Engineered for efficiency with advanced thermal design software like HTRI and ChemCAD.

- Compliance with global standards such as ASME, PED, and TEMA.

Each Shell & Tube Heat Exchanger is designed to align with stringent standards and industry requirements:

- Heat transfer capability: Optimized for liquid-liquid, gas-liquid, and steam applications.

- Pressure range: Up to 100 bar, suitable for high-pressure environments.

- Temperature range: 0°C to 450°C, accommodating a wide range of industrial processes.

- Material options: Stainless steel, titanium, Inconel, Duplex, and other high-grade alloys.

- Applications: Suitable for heating, cooling, condensing, reboiling, and other industrial processes.